Failure Mode and Structural Ductility of GFRP Reinforced Engineered Cementitious Composite Beams

Fiber Reinforced Plastic (FRP) reinforcements are a promising alternative to conventional steel reinforcing bar due to their inherent corrosion resistance and other advantageous features such as high strength and light weight. However, broad applications of FRP reinforcement is hindered by its elastic brittle behavior, which results in reduced structural ductility. In addition, its relatively low elastic modulus and anisotropy in strength may result in diminished structural shear capacity.

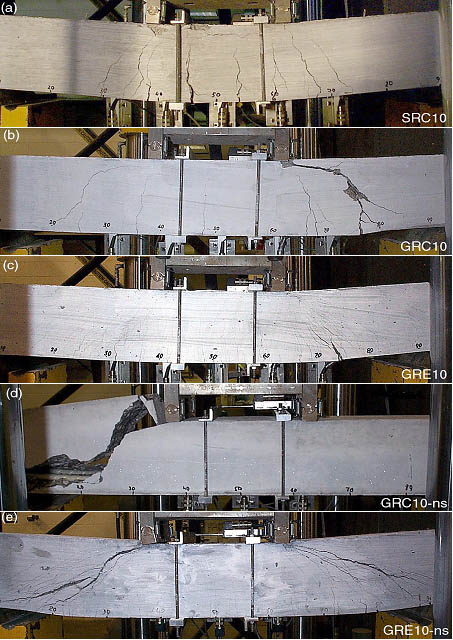

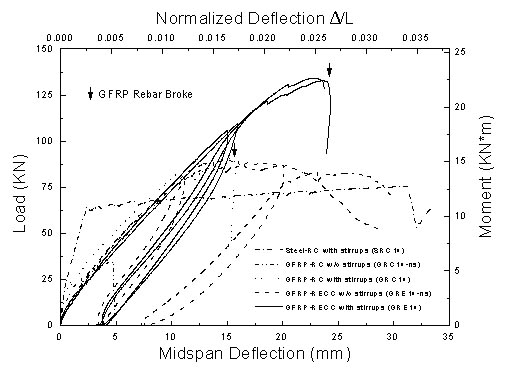

This research investigates new means to address these issues by introducing Engineered Cementitious Composite (ECC), which is designed based on micromechanics principles and exhibits superior tensile and shear ductility, to replace brittle concrete matrix. Three series totaling 16 GFRP reinforced beams with various shear span to depth ratio and longitudinal reinforcement ratio were tested. The results reveal that under the same reinforcement configuration the ECC beams exhibit significant improvement in flexural performance in terms of ductility, load-carrying capacity, shear resistance and damage tolerance (crack width, spalling) compared with the counterpart high strength concrete (HSC) beam. The extent of improvement strongly depends on the failure mode, that is, when the ultimate limit-state is dominated by matrix behavior, more significant improvement was observed. Moreover, ECC beams without shear reinforcement demonstrate superior performance to HSC beam with dense steel stirrups, suggesting that elimination of shear reinforcement is feasible when concrete matrix is replaced by ECC.