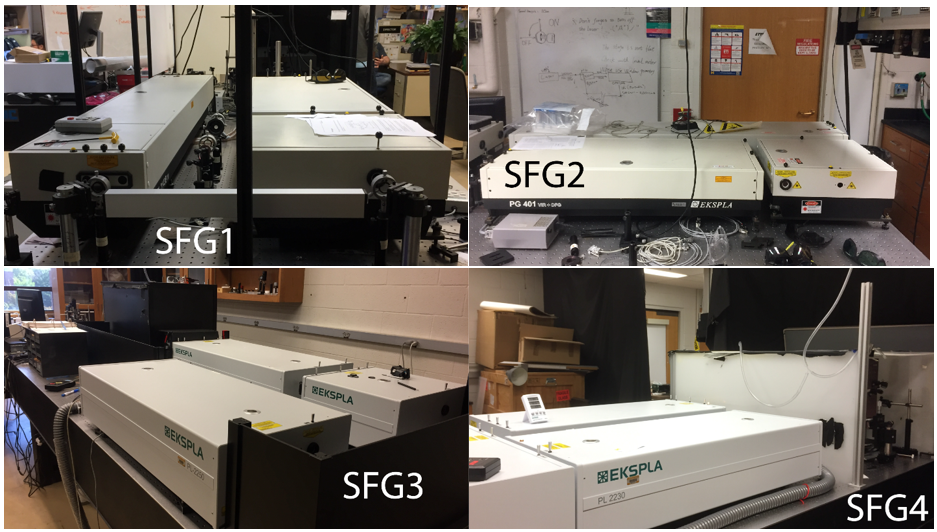

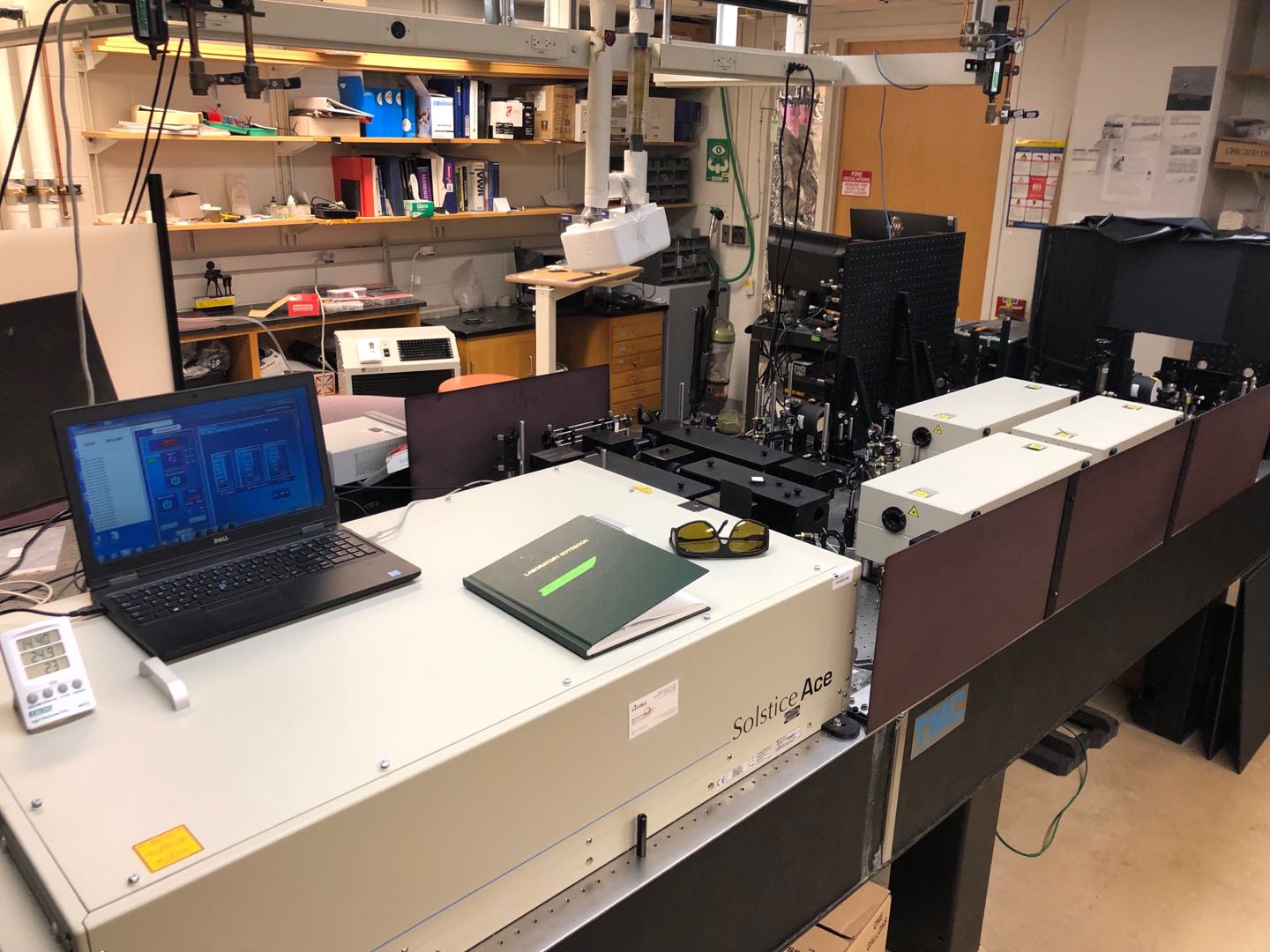

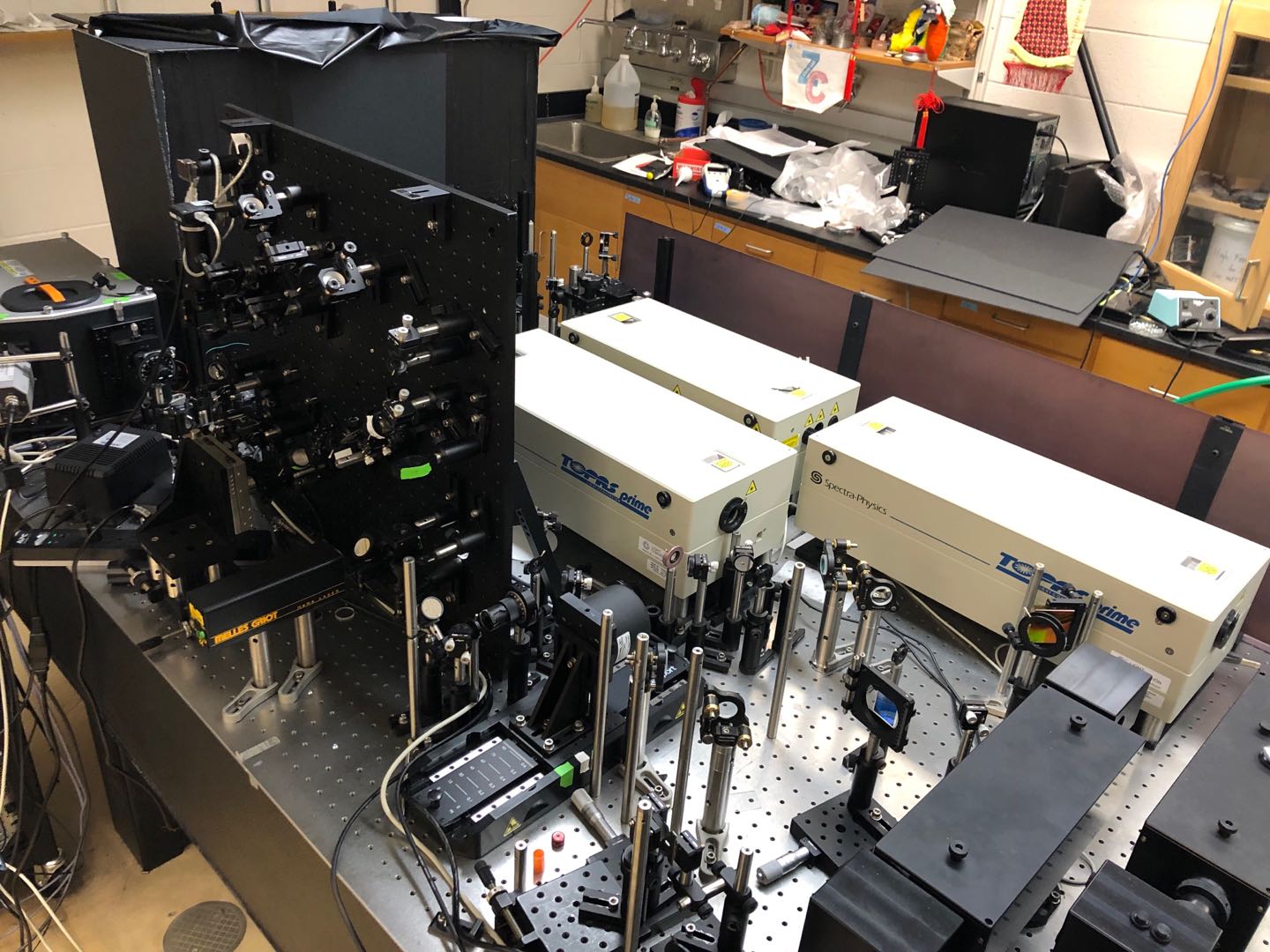

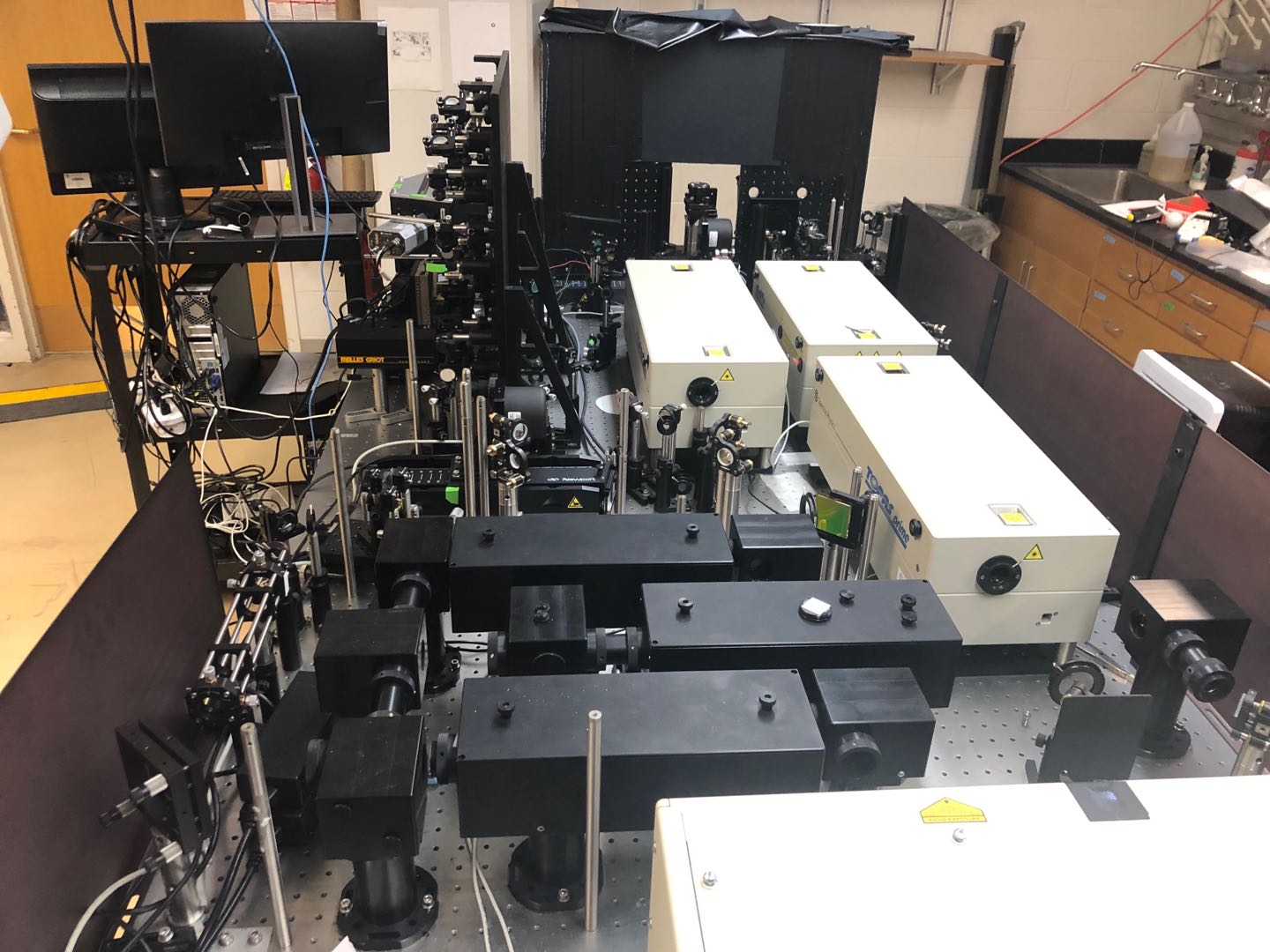

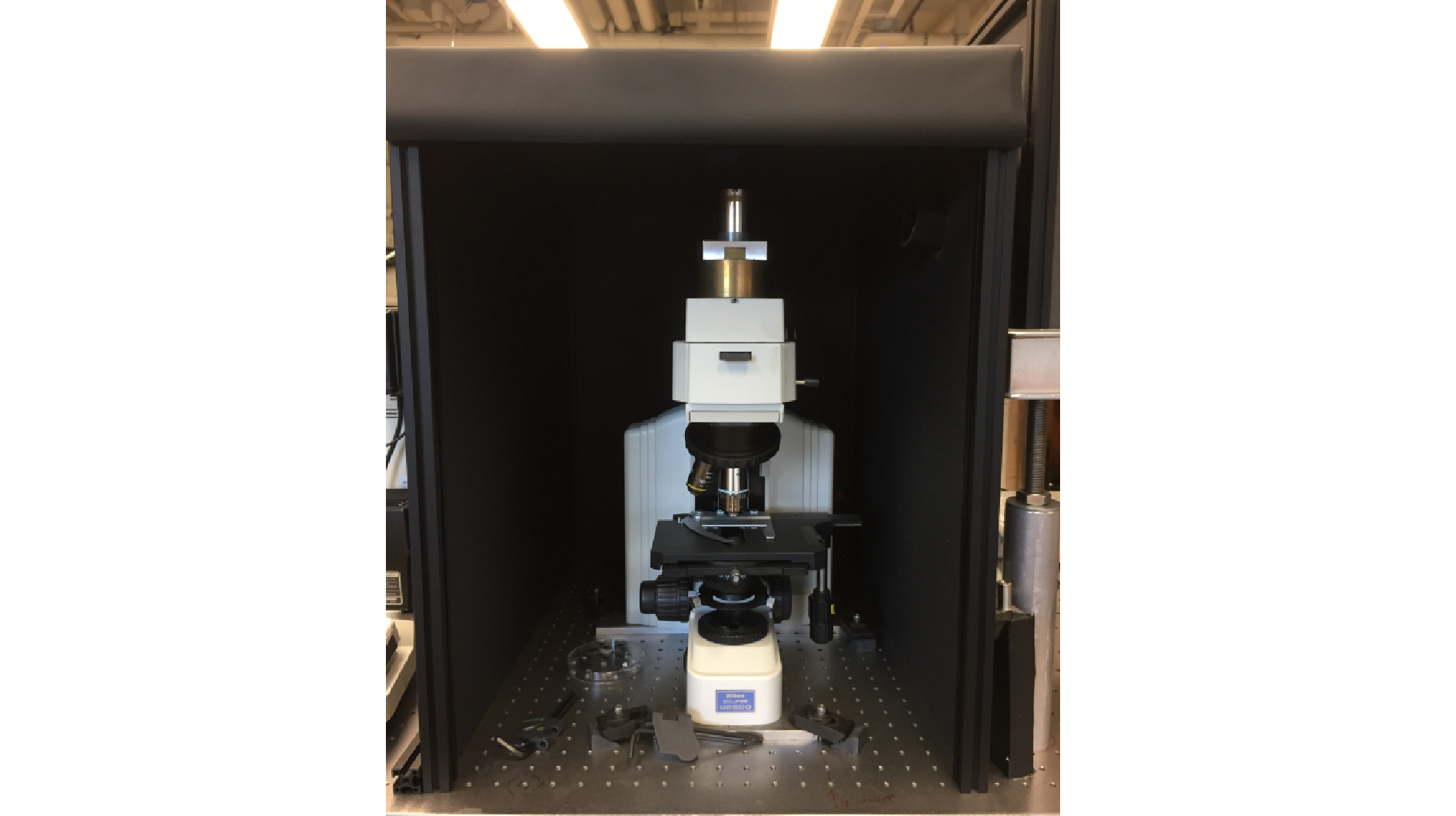

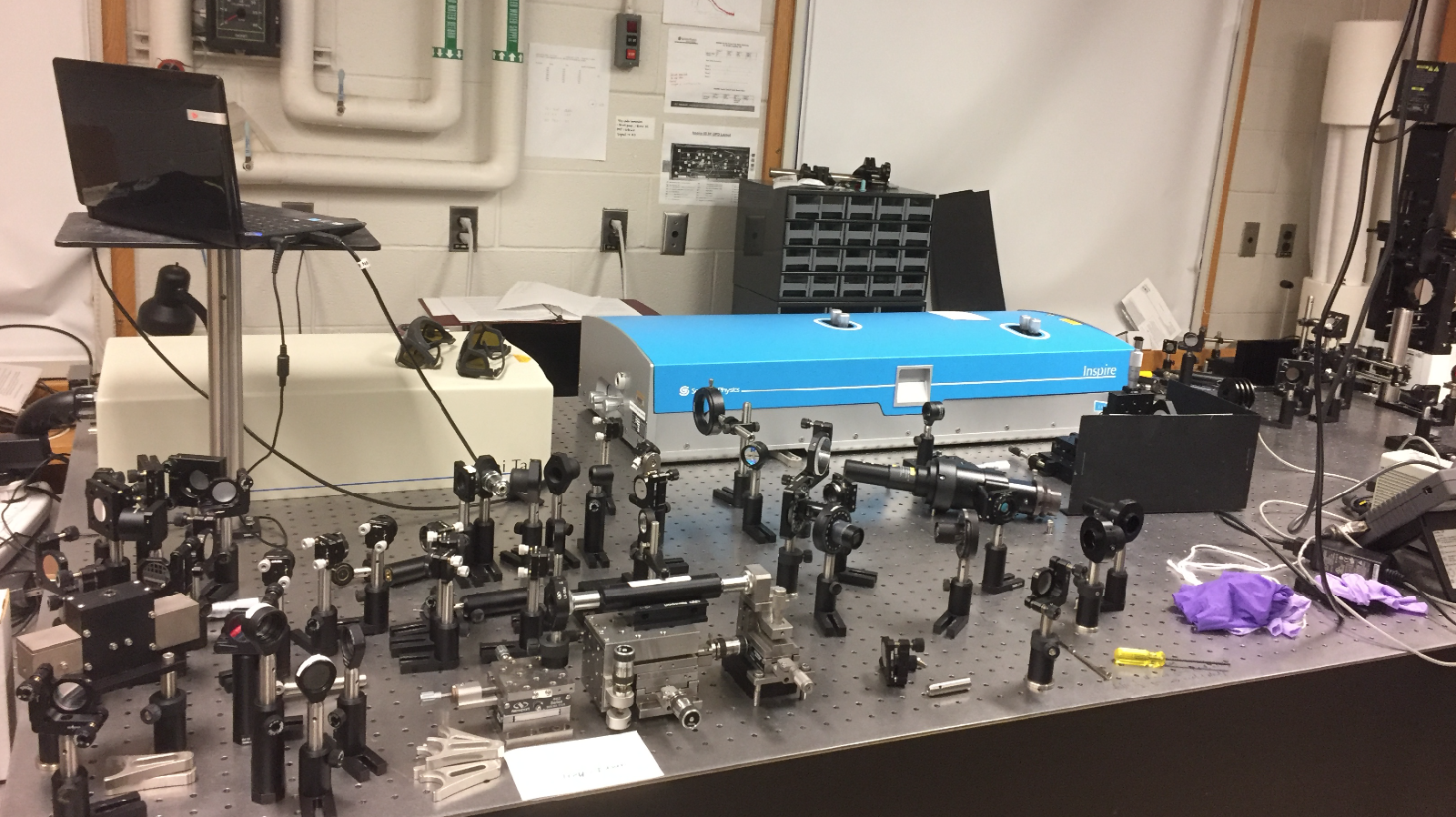

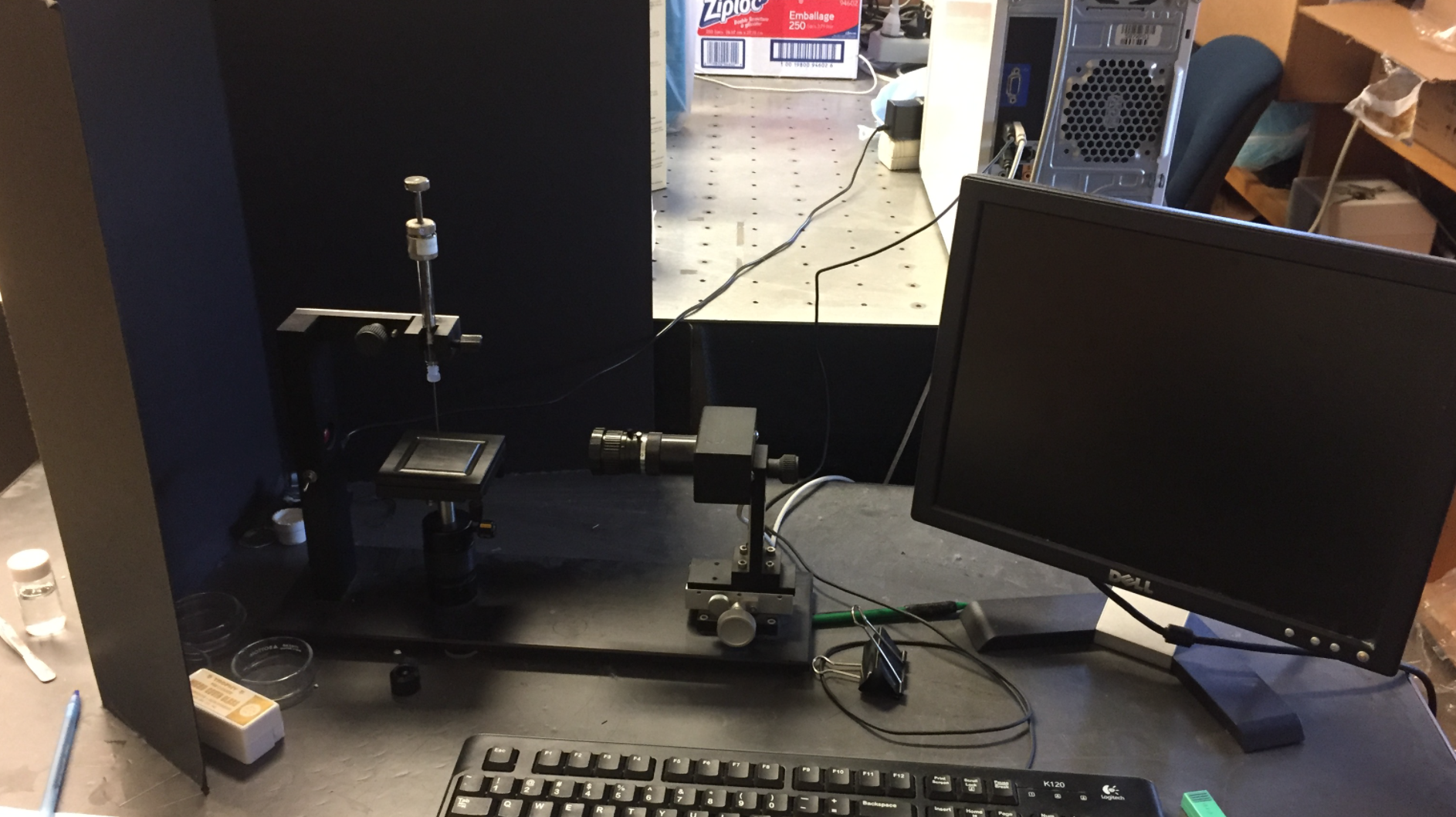

Sum Frequency Generation Vibrational Spectroscopy (SFG)

SFG is a process in which two input beams at frequencies w1 and w2 mix in a medium and generate an output beam at the sum frequency w = w1 + w2. As a nonlinear optical process, it is only allowed under electric-dipole approximation in media without inversion symmetry. At surfaces or interfaces, the inversion symmetry of the bulk is broken and therefore SFG is allowed.