OLED Fabrication

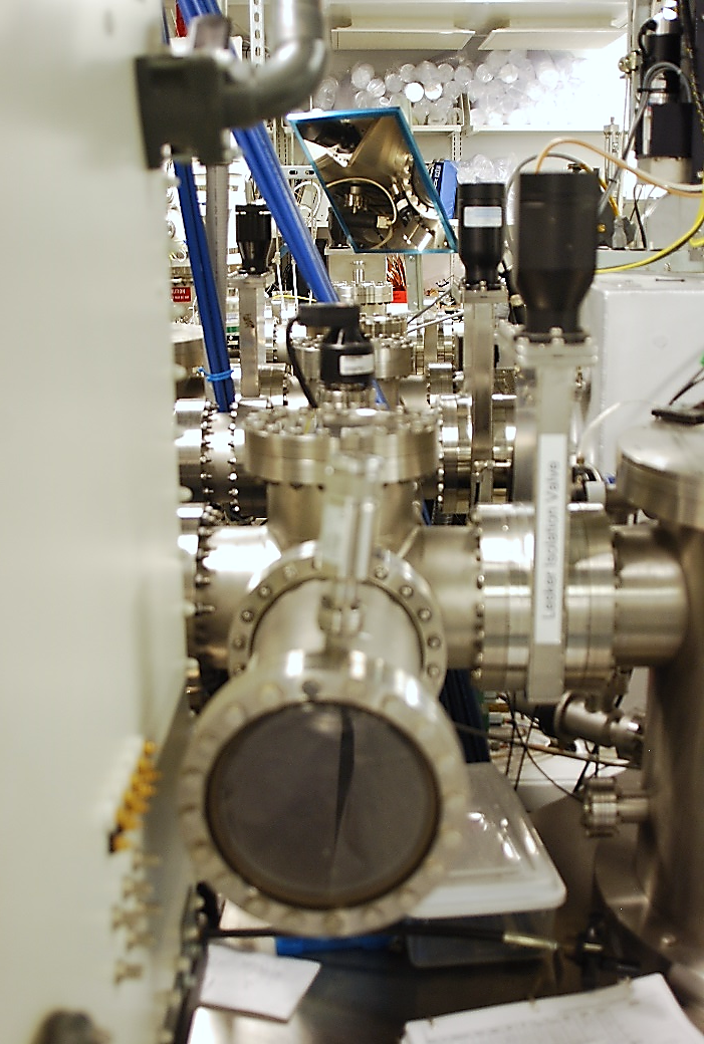

(above) High vacuum transfer tube for a cluster of deposition systems. Samples can be transferred between OVPD, metal, organic, sputter, and electron beam chambers without breaking vacuum, as well as a nitrogen glovebox. Complete devices can be grown without exposure to air.

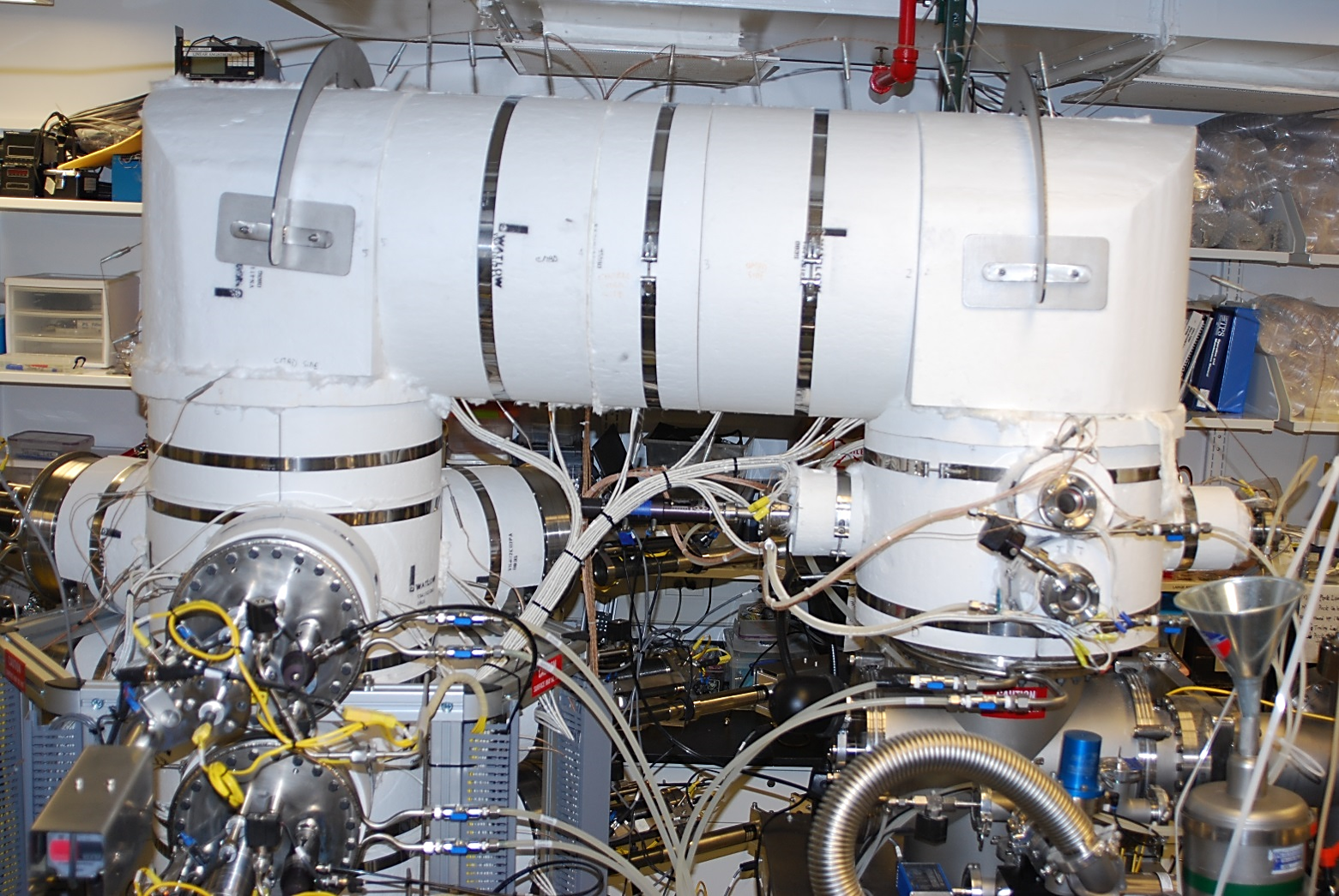

(above) An advanced organic vapor phase deposition (OVPD) system custom designed in partnership with and manufactured by Angstrom Engineering. OVPD is a gas phase organic thin film deposition technique for OLEDs and organic PV cells developed by OCM. This largely automated system makes the OVPD technique more accessable to new experimenters and provides valuable data to scale OVPD for mass fabrication of organic devices.

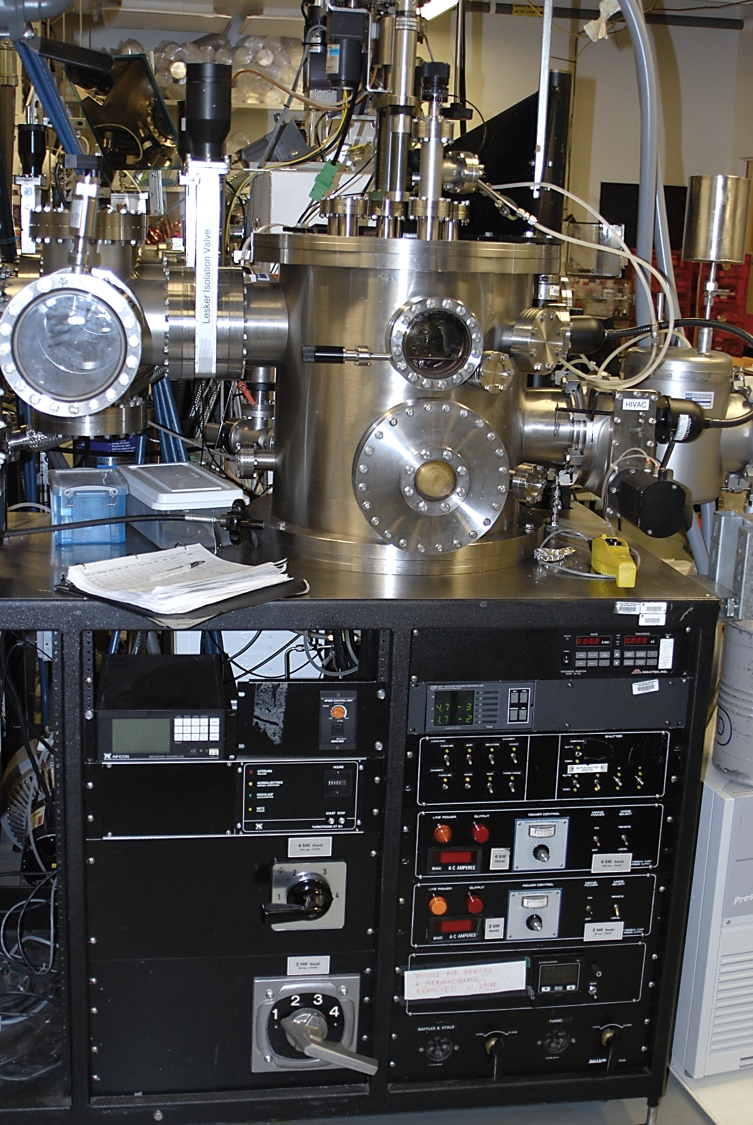

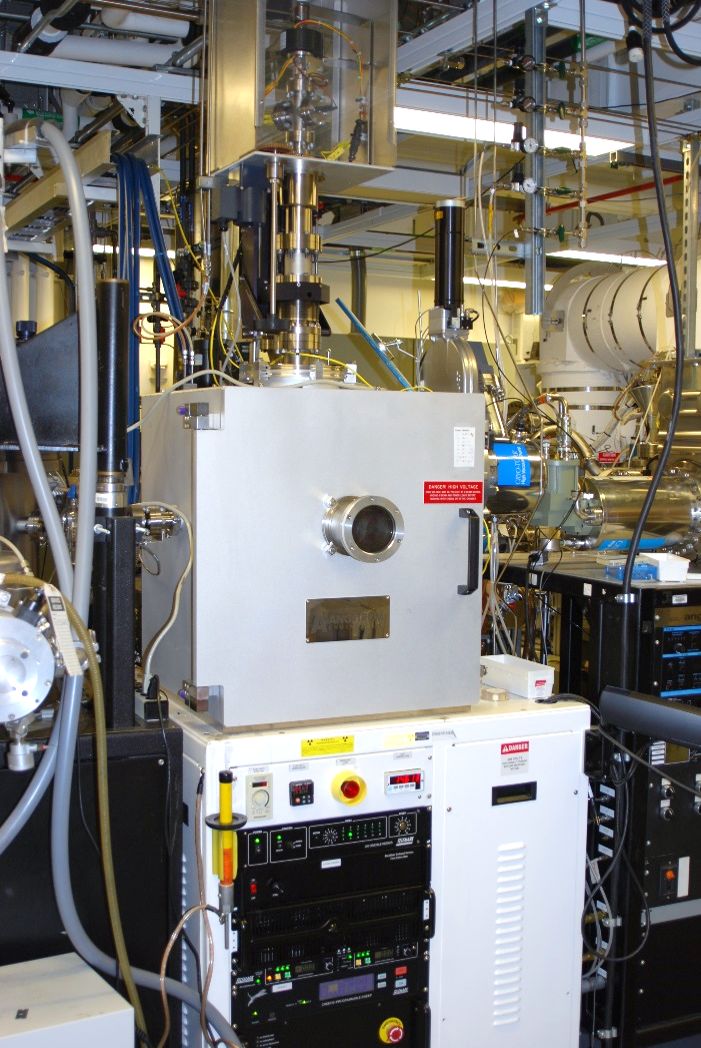

(above) A high power vacuum thermal evaporation system in the center used to deposit metal films.

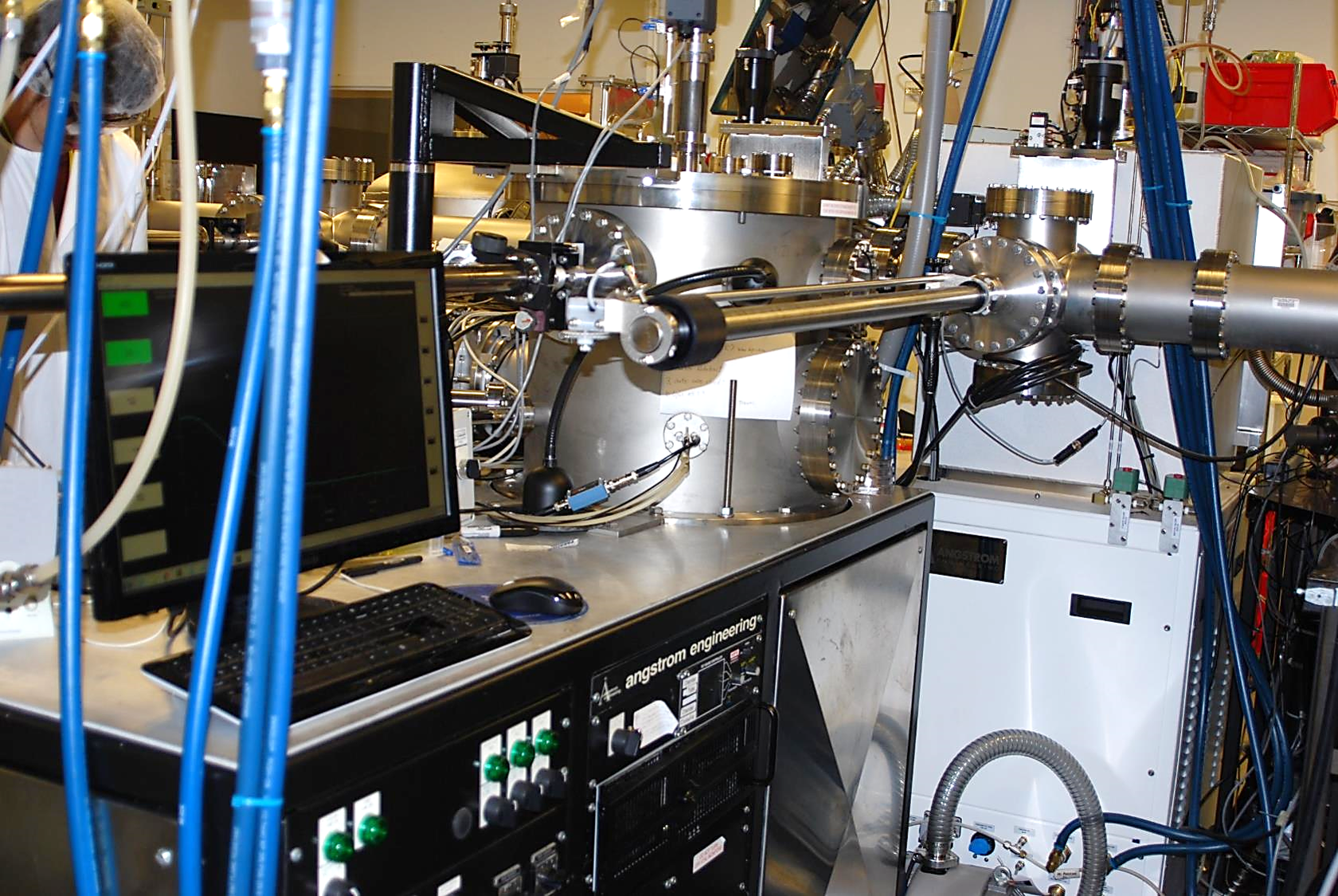

(above) 10 Source vacuum thermal evaporation system for deposition of organic materials. Organic materals can be deposited in neat films or mixed in user defined constant or graded ratios .

(above) A sputter deposition system on the OLED tool cluster. It is normally used to grow Indium Tin Oxide (ITO). ITO forms a transparent conducting film that is widely used in flat panel display applications.

(above) A 10 source electron beam vacuum deposition chamber capable of depositing metals and dielectrics used for photovoltaic and OLED research. The chamber also has two resistive thermal sources.

(above) Nitrogen glovebox connected to the OLED system tranfer tube though a load lock. Samples can be unpackaged, masked, and encapsulated in an oxygen and moisture free environment.