Organic Photovoltaic and Photodetector Fabrication

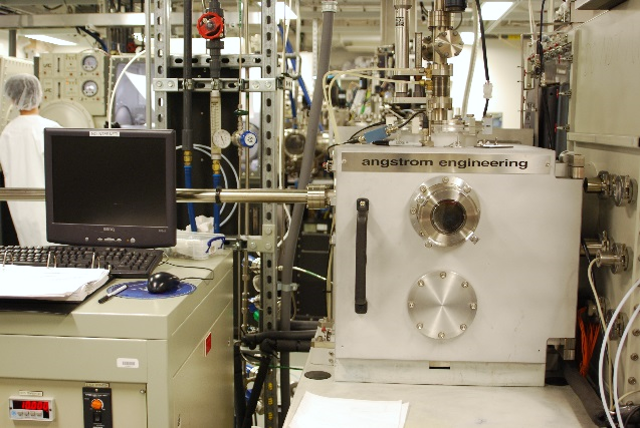

(above) Angstrom Engineering EvoVac tool deposits organic materials and metals by vacuum thermal evaporation for use in organic solar cells. This tool is connected to a cluster of glove boxes which allow samples to be loaded, handled, and transferred without exposure to air.

(above) A parylene deposition system is attached to the glovebox cluster. Parylene is used as a dielectric material and encapsulant for organic devices.

(above) Glovebox cluster features a spin coater and other equipment for solvent processing. Vacuum thermal evaporation, solvent processing, and parylene coating can be performed on devices without removal from an inert atmosphere.

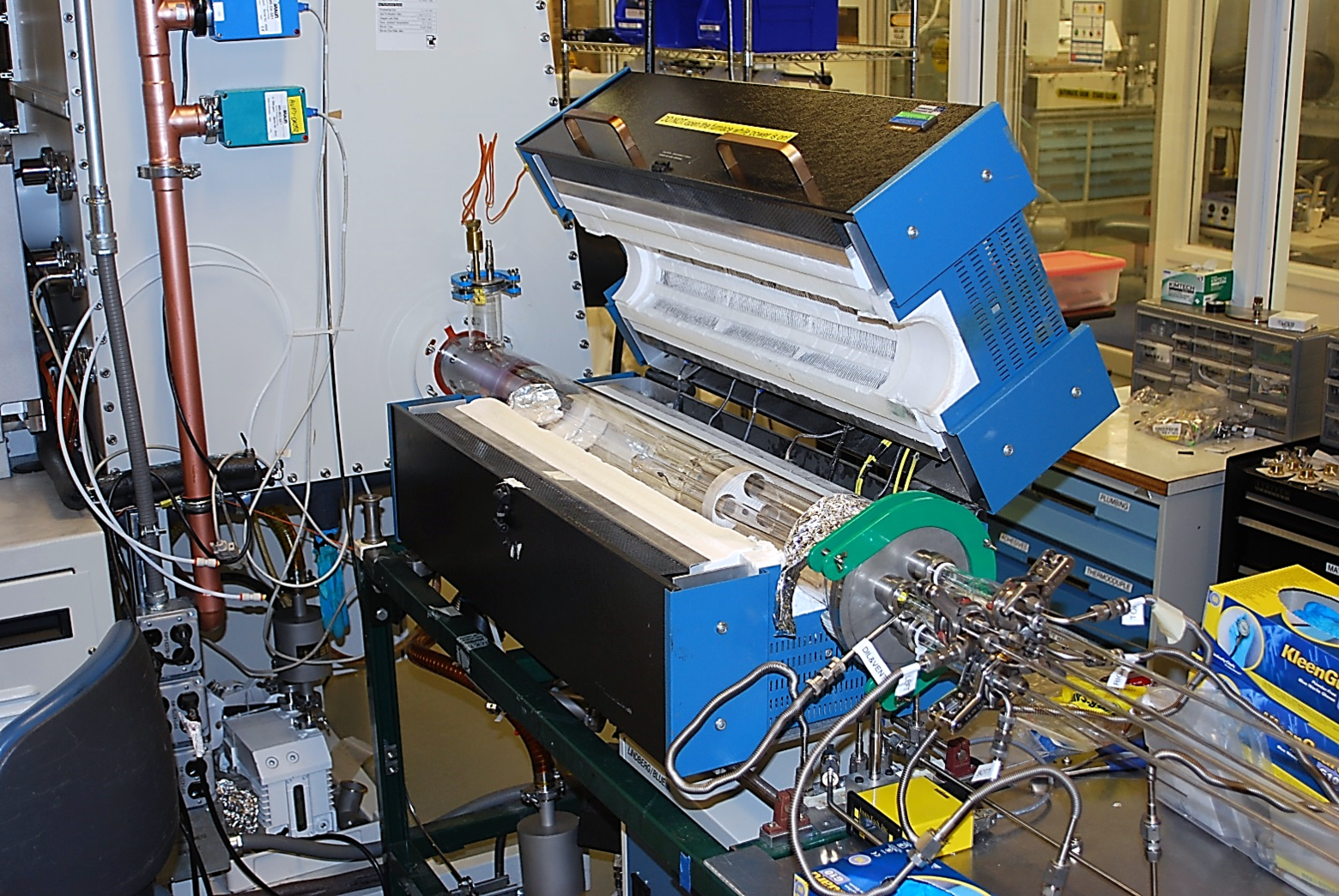

(above) Organic vapor phase deposition (OVPD) chamber. OVPD is a growth technique developed by OCM that allows for more efficient materials usage and greater control of surface morphology than vacuum thermal evaporation. Organic vapor is entrained in an inert carrier gas which carries it to a substrate. The pressure of the carrier gas can be adjusted from the millitorr range to tens of torr, changing its mass transport properties. OVPD has proven very useful for growing crystalline thin films and is a major focus OCM's organic photovoltaic cell research.

(above) The OVPD is connected to a dedicated Angstrom Amod vacuum thermal evaporator through the glovebox for the deposition of additional layers of organic or metal without exposing substrates to air.

(above) The dip coater allows the growth of homogeneous films using solution based processes, such as sol-gel and self assembled monolayers.