(5% to 40% MeCN in H2O, 0.1% TFA, 30 minute ramp) to yield compound 10 (81 mg, 0.139 mmol, 64%, RT = 11.0 min) and recovered 8 (21 mg, 16%, RT = 14.3 min). Spectroscopic and chromatographic data for this compound exactly matched the published data.

(5% to 40% MeCN in H2O, 0.1% TFA, 30 minute ramp) to yield compound 10 (81 mg, 0.139 mmol, 64%, RT = 11.0 min) and recovered 8 (21 mg, 16%, RT = 14.3 min). Spectroscopic and chromatographic data for this compound exactly matched the published data.

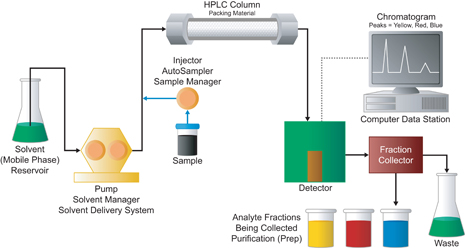

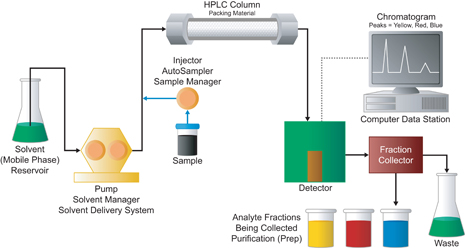

Compound 7 (130 mg, 0.218 mmol, 1.0 equiv) was dissolved in water (4.0 mL) and TFA (4.0 mL). The reaction was sealed under air and heated to 50 ºC for 12 h, after which the solvent was removed under reduced pressure to yield a highly viscous yellow oil. Water (23.4 mL) and TFA (2.6 mL) were added and the oil was sonicated into solution. Silver(II)picolinate (185 mg, 0.523 mmol, 2.4 equiv) was then added under air, and the murky red solution was sonicated for 30 seconds followed by stirring until it became translucent and colorless (approx 2 min total). The solvent was then removed under reduced pressure, and the crude reaction mixture was purified by preparative HPLC (5% to 40% MeCN in H2O, 0.1% TFA, 30 minute ramp) to yield compound 10 (81 mg, 0.139 mmol, 64%, RT = 11.0 min) and recovered 8 (21 mg, 16%, RT = 14.3 min). Spectroscopic and chromatographic data for this compound exactly matched the published data.

(5% to 40% MeCN in H2O, 0.1% TFA, 30 minute ramp) to yield compound 10 (81 mg, 0.139 mmol, 64%, RT = 11.0 min) and recovered 8 (21 mg, 16%, RT = 14.3 min). Spectroscopic and chromatographic data for this compound exactly matched the published data.

Su, S.I.; Seiple, B.; Young, I. S.; Baran, P. S. J. Am. Chem. Soc. 2008, 130, 16490-16491.

Want to learn about those pesky oxidations that the transitions metals that make up your car are performing, rusting up your paint job? Meghan and Lisa will tell you all about it in Organic Chemistry for Gear Heads!

|The Track| |About Us| |Transition Metal Oxidations| |The First Step| |References| |TV Guide|